Atlantic ATSL 3013 guillotine shear

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

plate thickness 13.0 mm

thickness at "Niro-steel" 6.0 mm

cutting angle 0.5 - 3.0 °

down holder 18 Stück

no. of strokes 9 - 17 Hub/min

back stop - adjustable max. 1000 mm

Control konv.

work height max. 930 mm

engine output 22.0 kW

weight 8000 kg

range L-W-H 4150 x 2020 x 2240 mm

Equipment:

- electro-hydraulic / slide-guided sheet metal shears

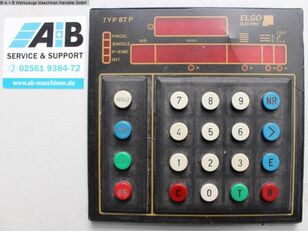

- front control panel, pivoting - front left

- with electro-hydraulic cutting angle adjustment

- with manual cutting gap adjustment, adjustable from behind

- electro-motorized rear stop 10-1000 mm

* 2x stable guide arms (with guides and drive spindle)

* stop rail adjustable in parallel

* with analog position display + handwheel for fine adjustment

* display on a counter up to 0.1 mm

- 1x side stop

- 1x freely movable foot switch

- front finger guard

- operating instructions (PDF)

The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

Hubzahl 9 - 17 Hub/min

Hinteranschlag - verstellbar max. 1000 mm

Steuerung konv.

Motorleistung 22.0 kW

Gewicht 8000 kg

Abmessung L-B-H 4150 x 2020 x 2240 mm