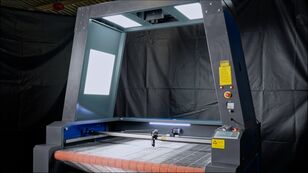

Amada Ensis 3015 AJ 9kW + ASLUL fiber laser machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Year 4/2019

Machine hours: about 39.000h / 26.000h / 15.000 h

Technical Data:

Working range: 3070 mm x 1550 mm

Table loading weight: 920 kg

Positioning speed: 170 m/min

Laser principle: Flying optic

Machine weight: 9.500 kg

Oscillator:

Laser source: laser diode-pumped fiber laser

Type: AJ-9000

Laser power: 9000 Watt

Laser wave length: 1,08 µm

Stability: +/- 2%

Pulse frequency: 1 – 10.000 Hz

Duty range: 1-100%

Control:

Type: AMNC-3i

Screen: 21,5” touchscreen

Operating system: Windows 7

Equipment:

NC-focus control

Oil spraying function

Sensor cutting head

Diode for positioning

Cutting process monitoring

Safety device

Nozzle changer

Conveyor belt

WACS

Peripherical devices:

Transformator

Cooling unit

Dust collector

Max. material thickness:

Mild steel: 25 mm

Stainless steel: 25 mm

Aluminium: 25 mm

Brass: 18 mm

Copper: 12 mm

Storage system ASLUL 3015:

Technical data:

Number of pallets: 8

Cutting pallets: 2

Max. weight of cutting pallets: 710 kg

Number of raw material pallets: 3

Max. weight of raw material pallets: 3000 kg

Max. stack height of raw material pallets: 150 mm

Number of unloading pallets: 3

Max. weight of unloading pallets: 3000 kg

Max. stack height of unloading pallets: 220 mm

Raw sheet dimensions min. / max.: 2000 x 1000 / 3000x 1500 mm

Min. part dimensions: 225 x 180 mm

Sheet thickness: 0,8 – 25,0 mm (for automatic mode 20,0 mm)

Max. sheet weight loading: 920 kg

Cycle time: 2 min 30 s

Time for pallet exchange: 55 s

Double sheet detection: yes, with sheet thickness measuring device

Air consumption: 1000 l/min, 6 bar

Electric connection: 400 V

Baujahr 4/2019

Betriebsstunden: ca. 39.000h / 26.000h / 15.000h

Technische Daten:

Verfahrbereich: 3070 mm x 1550 mm

Tischbelastung: 920 kg

Positioniergeschwindigkeit: 170 m/min

Laserprinzip: Fliegende Optik

Maschinengewicht: 9.500 kg

Laserquelle:

Strahlquelle: Dioden gepumpter Faserlaser

Typ: AJ-9000

Laserleistung: 9000 Watt

Laserwellenlänge: 1,08 µm

Leistungsstabilität: +/- 2%

Pulsfrequenz: 1 – 10.000 Hz

Impuls-Tastverhältnis (Duty): 1-100%

Steuerung:

Typ: AMNC-3i

Bildschirm: 21,5” Touchscreen

Betriebssystem: Windows 7

Ausstattung:

NC-Fokus Kontrolle

Ölsprühfunktion

Sensorschneidkopf

Diodenlaser zur Positionierung

Schneidprozessüberwachung

Sicherheitseinrichtung

Automatischer Düsenwechsler

Förderband

WACS

Peripheriegeräte:

Transformator

Kühler

Absaugung

Maximale Materialstärken:

Normalstahl: 25 mm

Edelstahl: 25 mm

Aluminium: 25 mm

Messing: 18 mm

Kupfer: 12 mm

Be- und Entladesystem ASLUL 3015:

Technische Daten:

Anzahl Paletten: 8

Schneidpaletten: 2

Max. Gewichtsbelastung der Schneidpaletten: 710 kg

Anzahl Rohmaterialpaletten: 3

Max. Gewichtsbelastung der Rohmaterialpaletten: 3000 kg

Max. Stapelhöhe der Rohmaterialpaletten: 150 mm

Anzahl Entladepaletten: 3

Max. Gewichtsbelastung der Entladepaletten: 3000 kg

Max. Stapelhöhe der Entladepaletten: 220 mm

Blechabmessungen min. / max.: 2000 x 1000 / 3000x 1500 mm

Min. Produktabmessung: 225 x 180 mm

Blechdicke: 0,8 – 25,0 mm (für Automatikmodus 20,0 mm)

Max. Blechgewicht Beladung: 920 kg

Zykluszeit: 2 min 30 s

Palettenwechselzeit: 55 s

Doppelblechkontrolle: ja, über Blechdickenmessgerät

Druckluftverbrauch: 1000 l/min, 6 bar

Elektroanschluß: 400 V