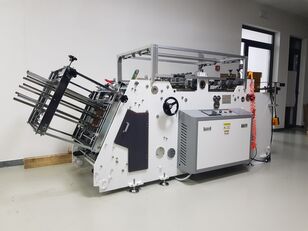

LMC PP3-004 1225 FFG cardboard box making machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

LMC PP3-004 1225 FFG

Strapping Machine SIGNODE ISB 1300 MONO

Palletizing System FANUC M-410iB/160

Feeder

3-color printing

Rotary die-cutting

Double slotter

Folding line with bundle separator

Strapping

Palletizing

Year of Manufacture: 2005

Year of Manufacture: 2005

Total Weight: 8,000 kg

Total Weight: 8,000 kg

Installed Power: 24 kW

Installed Power: 24 kW

Air Pressure Required: 6 bar

Air Pressure Required: 6 bar

Air Consumption: 150 l/min

Air Consumption: 150 l/min

Oil Pressure: 65 bar

Oil Pressure: 65 bar

Oil Volume: 40 liters

Oil Volume: 40 liters

Max. Format: 2500 x 1600 mm

Max. Format: 2500 x 1600 mm

Min. Format: 600 x 280 mm

Min. Format: 600 x 280 mm

Manufactured in 2005, this LMC machine includes:

Automatic feeder with SUN Automation lead edge feeder

Automatic feeder with SUN Automation lead edge feeder

Three printing units

Three printing units

Double slotter

Double slotter

Rotary die-cutter

Rotary die-cutter

Folding line with bundle separator

Folding line with bundle separator

Equipped with a NORDSON automatic gluing system with glue path detection

Equipped with a NORDSON automatic gluing system with glue path detection

Max. Sheet Size: 1200 x 2500 mm

Max. Sheet Size: 1200 x 2500 mm

Board Thickness: Up to 9 mm

Board Thickness: Up to 9 mm

Max. Speed: 220 sheets/minute

Max. Speed: 220 sheets/minute

Year of Manufacture: 2005

Year of Manufacture: 2005

Total Weight: 1,750 kg

Total Weight: 1,750 kg

Power Supply:

400V, 3-phase, 50 Hz

460V, 3-phase, 60 Hz

Power Supply:

400V, 3-phase, 50 Hz

400V, 3-phase, 50 Hz

460V, 3-phase, 60 Hz

460V, 3-phase, 60 Hz

Installed Power: 3–5 kVA

Installed Power: 3–5 kVA

Air Supply: 5–7 bar

Air Supply: 5–7 bar

Package Size Range:

Minimum: 170 x 170 x 50 mm (W x L x H)

Minimum: 170 x 170 x 50 mm (W x L x H)

Maximum: 1300 x 1400 x 350 mm (W x L x H)

Maximum: 1300 x 1400 x 350 mm (W x L x H)

Max. Output: 30 packages/min

Max. Output: 30 packages/min

Installed by NE Engineering in 2005, this robotic palletizing system includes:

Horizontal turntable

Horizontal turntable

Superposition station

Superposition station

FANUC robot with gripper head

FANUC robot with gripper head

Palletizing Capacity:

Max. Stack Height: 2200 mm

Max. Stack Height: 2200 mm

Max. Stack Footprint: 1650 x 1100 mm

Max. Stack Footprint: 1650 x 1100 mm

Configurable stacking patterns

Configurable stacking patterns

The machine is connected, can be inspected and test-run at any time, and is immediately available.

Category: Casemaker Inline

Max. Size: 2500 x 1600 mm

Min. Size: 600 x 280 mm

Condition: Good

Location: Europe

Availability: Immediately